Fibreglass Roofers Your Guide to Roofing Excellence

Fibreglass roofers are specialists in a durable and increasingly popular roofing material. This guide dives into everything you need to know about fibreglass roofing, from understanding its properties and benefits to finding the right installer and maintaining your new roof for years to come. We’ll cover installation techniques, cost considerations, and even address common misconceptions about this robust roofing solution. Whether you’re a homeowner considering a roof replacement or a contractor looking to expand your skillset, this comprehensive overview will equip you with the knowledge you need.

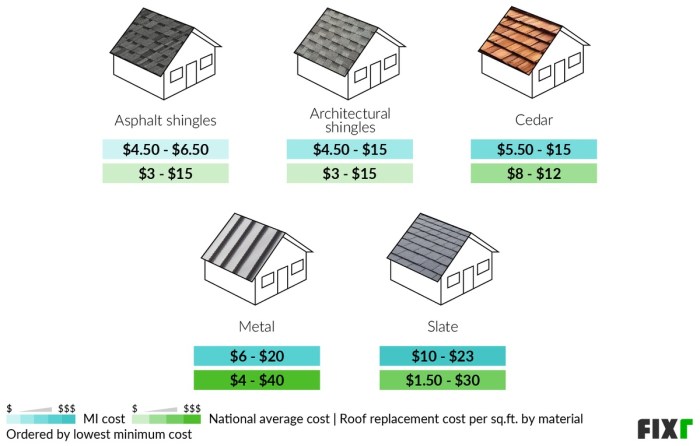

We’ll explore the advantages of fibreglass over other materials like asphalt shingles and metal roofing, detailing its longevity, cost-effectiveness, and relatively low maintenance requirements. We’ll also cover crucial aspects of the installation process, highlighting potential pitfalls and offering solutions to ensure a smooth and successful project. Finally, we’ll help you navigate the process of finding and vetting qualified fibreglass roofers, ensuring you make the right choice for your roofing needs.

Understanding Fibreglass Roofing

Fibreglass roofing, also known as fiberglass reinforced polyester (FRP), is a popular roofing material offering a blend of durability and affordability. It’s a composite material, making it a strong contender in the roofing market. Let’s delve into its composition, advantages, installation, and compare it to other roofing options.

Fibreglass Roofing Composition and Properties, Fibreglass roofers

Fibreglass roofing consists of a mat of fiberglass strands embedded in a resin matrix, typically polyester or vinyl ester. This combination creates a strong, lightweight, and relatively flexible sheet. The resin provides weather resistance and protects the fiberglass from degradation. The resulting material is resistant to corrosion, rot, and many chemicals, making it suitable for a wide range of applications. Its flexibility allows it to conform to various roof shapes and sizes. Different finishes, such as gel coats, are applied to enhance aesthetics and UV resistance.

Advantages and Disadvantages of Fibreglass Roofing

Fibreglass roofing offers several advantages. Its lightweight nature simplifies installation, reducing labor costs and potential structural stress on the building. Its durability ensures a long lifespan, often exceeding that of asphalt shingles. The material’s resistance to corrosion, rot, and many chemicals makes it a low-maintenance option. Furthermore, it’s available in a variety of colors and styles to complement various architectural designs. However, fibreglass roofing is not without its drawbacks. It can be more expensive upfront than asphalt shingles, although the long lifespan often offsets this cost over time. It’s also susceptible to damage from impacts, requiring careful handling during installation and maintenance. Finally, repairing damaged sections can be more complex than with some other roofing materials.

Fibreglass Roofing Installation

Proper installation is crucial for the longevity and performance of a fibreglass roof. Here’s a step-by-step guide:

- Preparation: Thoroughly clean and prepare the roof deck, ensuring it’s free from debris, loose materials, and any existing damage. This involves removing old roofing materials, repairing any structural issues, and ensuring a level surface.

- Underlayment: Install a suitable underlayment to provide an extra layer of protection against moisture penetration. This step is crucial for preventing leaks and extending the life of the fibreglass roofing.

- Measurement and Cutting: Accurately measure and cut the fibreglass sheets to fit the roof’s dimensions. Allow for overlaps to ensure complete coverage and watertight seals.

- Installation: Carefully position and secure the fibreglass sheets, ensuring proper overlaps and alignment. Use appropriate adhesives and fasteners according to the manufacturer’s instructions.

- Seaming and Sealing: Apply sealant to all seams and overlaps to create a waterproof barrier. This step is critical to prevent leaks and maintain the roof’s integrity.

- Finishing: Once the installation is complete, inspect the roof for any imperfections or areas needing further attention. Address any issues promptly to ensure a long-lasting and reliable roof.

Fibreglass Roofing vs. Other Roofing Materials

The following table compares the lifespan, cost, and maintenance requirements of fibreglass roofing with asphalt shingles and metal roofing. These figures are estimates and can vary based on factors like quality of materials, installation, and climate.

| Roofing Material | Lifespan (Years) | Initial Cost (Relative) | Maintenance Requirements |

|---|---|---|---|

| Fibreglass | 20-30 | Medium | Low |

| Asphalt Shingles | 15-20 | Low | Medium |

| Metal Roofing | 50+ | High | Low |

Finding and Vetting Fibreglass Roofers

Source: forbes.com

Finding a reliable fibreglass roofing contractor can be crucial for a successful and long-lasting roof installation. A poorly chosen contractor can lead to costly repairs, leaks, and significant headaches down the line. This section will guide you through the process of identifying and vetting potential roofers to ensure you make an informed decision.

Finding Reputable Fibreglass Roofers in a Specific Area

Locating qualified fibreglass roofers, particularly in a bustling area like London, UK, requires a multi-pronged approach. Online directories, such as Checkatrade or Rated People, offer reviews and ratings from previous clients, providing valuable insights into a contractor’s reputation and workmanship. Local builders’ merchants often have strong relationships with local contractors and can offer recommendations. Networking within your community, asking neighbours or friends for referrals, can also yield promising leads. Finally, checking professional bodies such as the National Federation of Roofing Contractors (NFRC) for accredited members in your area can help ensure you’re dealing with a reputable and qualified professional.

Evaluating the Qualifications and Experience of Potential Roofers

A thorough evaluation of a contractor’s qualifications and experience is essential. This checklist will help you assess their suitability:

- Check for Accreditation: Verify membership with professional bodies like the NFRC, which indicates adherence to industry standards and best practices.

- Insurance and Liability Coverage: Ensure they possess adequate public liability and employers’ liability insurance to protect you from potential risks.

- References and Testimonials: Request contact details for previous clients and review their testimonials to gauge the quality of their work and customer service.

- Experience with Fibreglass Roofing: Confirm their specific experience with fibreglass roofing materials and techniques; years of experience alone doesn’t guarantee expertise in this specific area.

- Qualifications and Training: Inquire about their qualifications and any relevant training certificates related to fibreglass roofing installation.

- Warranty and Guarantees: Understand the warranty offered on materials and workmanship; a reputable contractor will stand behind their work.

Obtaining Multiple Quotes and Comparing Services

Gathering multiple quotes is paramount. At least three quotes from different contractors allow for a comprehensive comparison of pricing, materials, and services. Avoid choosing solely based on price; consider the overall package, including the warranty, experience, and reputation of the contractor. Comparing detailed breakdowns of the quotes, including materials and labour costs, helps to identify potential discrepancies or hidden charges. For example, one quote might specify using higher-quality fibreglass, impacting the overall cost but potentially leading to a longer-lasting roof.

Essential Questions to Ask Prospective Fibreglass Roofers

Before committing to a contractor, clarifying several key aspects is crucial. These questions should be addressed to ensure a smooth and satisfactory project:

- Project Timeline: Confirm the estimated start and completion dates of the project.

- Detailed Breakdown of Costs: Request a comprehensive breakdown of all costs, including materials, labour, and any potential additional expenses.

- Payment Schedule: Understand the agreed payment schedule and payment methods accepted.

- Waste Disposal: Inquire about their waste disposal plan and compliance with environmental regulations.

- Health and Safety Procedures: Confirm their adherence to health and safety regulations on site.

- Method Statement: Request a detailed method statement outlining the steps involved in the installation process.

The Fibreglass Roofing Process: Fibreglass Roofers

Installing a fibreglass roof is a multi-stage process requiring skill and precision. A successful installation depends on careful preparation, proper material selection, and meticulous execution of each step. Understanding these stages will help you better assess the quality of work performed by a contractor.

Fibreglass Roofing System Types

Several fibreglass roofing systems exist, each with its characteristics and applications. The choice depends on factors like budget, roof design, and climate. Common types include reinforced fibreglass roofing sheets, often used for sheds and outbuildings, and more complex, layered systems incorporating insulation and waterproofing membranes for larger residential or commercial applications. Some systems also integrate solar reflective properties to reduce energy costs. The specific system chosen will significantly impact the installation process.

Roof Preparation for Fibreglass Installation

Thorough roof preparation is crucial for a long-lasting and leak-free fibreglass roof. This involves several key steps. First, the existing roof surface must be thoroughly cleaned to remove debris, loose materials, and any existing coatings that might compromise adhesion. This often involves sweeping, pressure washing (carefully, to avoid damage), and potentially scraping off loose paint or asphalt. Secondly, any damaged areas of the underlying structure – whether wood sheathing, plywood, or other substrates – must be repaired. This might involve replacing damaged sections, patching holes, and ensuring a smooth, even surface for the fibreglass to adhere to. Finally, any existing flashing around chimneys, vents, or other protrusions should be inspected and replaced if necessary to prevent leaks. Neglecting this stage can lead to premature failure of the new roof.

Stages of Fibreglass Roofing Installation

A typical fibreglass roofing installation proceeds in several distinct stages. First, the prepared roof surface receives a primer coat, promoting better adhesion of the fibreglass. Next, the fibreglass sheets or panels are carefully laid down, overlapping according to the manufacturer’s instructions. Seams are sealed with specialized adhesive tapes or sealants to create a watertight barrier. Depending on the system, insulation boards may be installed between layers of fibreglass. Finally, a topcoat, often a specialized paint or sealant, is applied to protect the fibreglass from UV degradation and weathering. Careful attention to detail at each stage is critical for a successful outcome.

Common Problems and Solutions During Fibreglass Roofing Installation

Several common problems can arise during fibreglass roofing installation. Improper preparation, such as insufficient cleaning or inadequate repair of underlying damage, can lead to poor adhesion and premature failure. Incorrect seam sealing can result in leaks. Using incompatible materials or failing to follow manufacturer’s instructions can also cause problems. For instance, using the wrong type of adhesive or sealant can lead to delamination or cracking. Solutions often involve identifying the root cause and rectifying it. This might involve removing and reapplying sections of the fibreglass, using the correct sealant, or addressing underlying structural issues. Proper planning and meticulous attention to detail are key to preventing these problems.

Maintenance and Repair of Fibreglass Roofs

Source: careeronestop.org

Fibreglass roofs, while durable, require regular maintenance to ensure longevity and prevent costly repairs. Proper care can significantly extend the lifespan of your roof and protect your investment. Neglecting maintenance can lead to premature deterioration and potential leaks, resulting in more extensive and expensive repairs down the line. This section includes essential maintenance practices and guides you through identifying and addressing common issues.

Regular Maintenance Procedures

Regular inspections are crucial for early detection of problems. Ideally, you should inspect your fibreglass roof at least twice a year, once in spring and once in autumn. During these inspections, check for any signs of damage, such as cracks, blisters, or loose seams. Also, look for any debris accumulation, like leaves or twigs, that can trap moisture and lead to damage. A thorough cleaning, as detailed below, should be performed at least annually. Addressing minor issues promptly prevents them from escalating into larger, more expensive problems.

Identifying and Addressing Common Damage

Several signs indicate potential problems with your fibreglass roof. Cracks, usually appearing as hairline fractures, can be caused by impact or temperature fluctuations. Blisters, which look like raised bubbles on the surface, often indicate trapped moisture underneath the fibreglass. Loose or damaged seams are another common issue, potentially leading to leaks. Algae and moss growth, while not directly damaging the fibreglass itself, can retain moisture and accelerate deterioration. Addressing cracks involves cleaning the area, applying a compatible patching compound, and ensuring a smooth finish. Blisters may require cutting and resealing, while loose seams need to be re-adhered using appropriate sealant. Algae and moss should be removed using a suitable cleaning solution to prevent moisture retention.

Cleaning Products and Methods

Choosing the right cleaning products is essential for maintaining your fibreglass roof without causing damage. Avoid harsh chemicals, abrasive cleaners, and high-pressure washers, as these can strip the protective coating or damage the fibreglass itself. A simple solution of mild detergent and water is often sufficient for regular cleaning. Apply the solution using a soft-bristled brush or sponge, gently scrubbing to remove dirt and debris. Rinse thoroughly with clean water to prevent residue buildup. For stubborn stains or algae, a specialized roof cleaning solution designed for fibreglass may be necessary, but always follow the manufacturer’s instructions carefully. Never use bleach or other harsh chemicals.

Preventative Measures for Fibreglass Roof Protection

Regular maintenance is key, but proactive measures further protect your investment.

- Regularly inspect your roof for any signs of damage.

- Clean your roof at least once a year to remove debris and prevent moisture buildup.

- Trim overhanging branches to prevent debris accumulation and potential damage from falling branches.

- Ensure proper gutter and downspout maintenance to prevent water damage.

- Address any minor repairs promptly to prevent them from escalating into larger problems.

- Consider applying a protective sealant every few years to enhance the roof’s longevity and water resistance. This provides an additional barrier against the elements.

Cost Considerations for Fibreglass Roofing

Fibreglass roofing, while offering numerous advantages in terms of durability and longevity, comes with a price tag. Understanding the cost breakdown is crucial for budgeting and making informed decisions. This section will explore the various factors influencing the overall expense of a fibreglass roofing project, allowing you to better estimate the investment involved.

The total cost of a fibreglass roofing project is a multifaceted figure, depending heavily on several key variables. It’s not a one-size-fits-all scenario, and obtaining accurate quotes from multiple reputable contractors is essential before proceeding.

Typical Cost Breakdown of Fibreglass Roofing Installation

A typical fibreglass roofing installation cost encompasses materials, labor, and permits. Material costs depend on the quality and type of fibreglass chosen, while labor costs are influenced by the project’s size and complexity. Permit fees vary depending on location and local regulations. Let’s examine these components in more detail.

Consider a 1500 square foot roof. Materials might cost between $3,000 and $6,000, depending on the quality of the fibreglass chosen. Labor costs could range from $4,000 to $8,000, depending on the complexity of the roof and the contractor’s rates. Permit fees could add another $500 to $1,500. This leads to a total estimated cost range of $7,500 to $15,500 for this example.

Long-Term Cost-Effectiveness Compared to Other Roofing Options

While the initial investment in fibreglass roofing may seem higher than some alternatives like asphalt shingles, its long lifespan and low maintenance requirements contribute to significant long-term cost savings. Asphalt shingles typically need replacement every 15-20 years, whereas fibreglass roofs can last 30 years or more with proper maintenance. This translates to fewer replacements and reduced long-term expenses.

For instance, replacing asphalt shingles twice over 30 years could cost significantly more than the initial investment in a fibreglass roof, considering material, labor, and disposal costs for the old shingles. This long-term perspective highlights the superior cost-effectiveness of fibreglass in many cases.

Factors Influencing the Overall Cost of a Fibreglass Roofing Project

Several factors significantly impact the final cost of a fibreglass roofing project. These include the size and complexity of the roof, the chosen quality of materials, labor rates in the specific region, the need for repairs or additional work, and the required permits and inspections.

| Factor | Impact on Cost |

|---|---|

| Roof Size and Complexity | Larger, more complex roofs naturally require more materials and labor, increasing costs. |

| Material Quality | Higher-quality fibreglass offers superior durability and longevity but comes at a higher initial price. |

| Labor Rates | Regional variations in labor costs significantly influence the overall expense. |

| Necessary Repairs | Pre-existing roof damage requiring repairs before installation will add to the total cost. |

| Permits and Inspections | Permit fees and inspection costs vary by location and regulations. |

Sample Budget for a Fibreglass Roofing Project

Creating a realistic budget is essential. This sample budget assumes a medium-sized, relatively simple roof of approximately 1000 square feet. Remember, these are estimates, and actual costs may vary.

| Item | Cost Estimate |

|---|---|

| Materials (Fibreglass, underlayment, fasteners) | $2,000 – $4,000 |

| Labor (Installation, cleanup) | $3,000 – $6,000 |

| Permits and Inspections | $300 – $1,000 |

| Contingency (Unexpected expenses) | $500 – $1,000 |

| Total Estimated Cost | $5,800 – $12,000 |

Visual Guide to Fibreglass Roofing

Source: alamy.com

Fibreglass roofing, when properly installed, offers a sleek and durable surface that can enhance the aesthetic appeal of any building. Understanding the visual aspects of fibreglass roofing is crucial for homeowners and contractors alike, ensuring the final product meets both functional and stylistic expectations. This guide will walk you through the various visual elements of a fibreglass roof, from color and texture to the overall impact on different architectural styles.

Fibreglass Roof Appearance and Color Options

A well-installed fibreglass roof presents a smooth, seamless surface, free from noticeable seams or imperfections. The color options are incredibly diverse, ranging from traditional earth tones like terracotta and brown to vibrant blues, greens, and even custom blends. The color is typically consistent across the entire roof surface, providing a uniform and aesthetically pleasing look. Textures can vary slightly depending on the topcoat used, ranging from a slightly pebbled appearance to a smoother, almost glossy finish. Imagine a rich, deep red roof that looks both modern and timeless, or a subtle grey that blends seamlessly with the surrounding landscape. These visual choices are significant for matching the roof with the building’s overall design.

Finishes and Coatings Available for Fibreglass Roofing

Several types of finishes and coatings are available to enhance the durability and appearance of fibreglass roofing. A common finish is a smooth, matte coating that provides excellent UV protection and color retention. Other options include textured finishes that mimic the appearance of traditional roofing materials like slate or tile, offering a more rustic or classic look. Some coatings offer added benefits, such as enhanced reflectivity to reduce heat absorption, or increased resistance to algae and moss growth. These finishes are not just about aesthetics; they also play a vital role in extending the lifespan and maintaining the visual appeal of the roof over time. For example, a high-gloss finish might reflect sunlight more effectively, keeping the attic cooler in hot climates.

Visual Impact of Fibreglass Roofing on Architectural Styles

Fibreglass roofing’s adaptability makes it suitable for a wide range of architectural styles. On a modern, minimalist home, a sleek, smooth, light grey fibreglass roof can complement the clean lines and simple design. In contrast, a more traditional home might benefit from a darker, textured fibreglass roof that mimics the look of slate tiles, maintaining a classic aesthetic. The color and texture choices can be tailored to seamlessly integrate the roof into the overall architectural scheme, whether it’s a Victorian-era home or a contemporary loft. The versatility of fibreglass allows for a harmonious blend of functionality and style, regardless of the building’s design.

Components of a Fibreglass Roofing System

A fibreglass roofing system comprises several key components, each contributing to its overall performance and appearance. The underlayment, typically a woven fabric, provides a base layer for the fiberglass matting, acting as a moisture barrier. It’s usually dark in color and not directly visible once the topcoat is applied. The fibreglass matting itself is a reinforced fiberglass mesh, providing structural integrity. It’s typically light grey or off-white and is completely hidden beneath the topcoat. The topcoat, the final visible layer, is what determines the color and texture of the roof. This layer is responsible for weather resistance, UV protection, and the overall aesthetic appeal. Visualize it as a layered cake: the underlayment forms the base, the fiberglass matting adds strength, and the topcoat provides the final, beautiful finish.

Final Review

Choosing the right roofing material is a significant investment, and understanding the nuances of fibreglass roofing is key to making an informed decision. This guide has equipped you with the knowledge to confidently navigate the process, from selecting a reputable installer to understanding the long-term costs and maintenance involved. Remember, a well-installed fibreglass roof can provide years of protection and enhance the aesthetic appeal of your property. By following the tips and advice outlined here, you can ensure a successful roofing project that stands the test of time.